Design Software For Woodworking Projects

Design software for woodworking projects empowers enthusiasts and professionals to create detailed plans and visualize their projects digitally. For instance, the software allows woodworkers to design furniture, cabinetry, and other intricate items with precision and efficiency.

This software offers numerous advantages, including enhanced accuracy, reduced waste, and improved collaboration. Historically, the advent of computer-aided design (CAD) technology has revolutionized woodworking design, enabling users to create complex shapes and geometries that were previously challenging to achieve manually.

In this article, we will explore the capabilities and benefits of design software for woodworking projects in greater depth, examining its impact on the industry and showcasing real-world applications.

Design Software for Woodworking Projects

Design software for woodworking projects plays a pivotal role in the modern woodworking industry, offering numerous advantages and capabilities. To fully understand its significance, it is crucial to explore its essential aspects:

- Accuracy: Precision in design and measurements.

- Efficiency: Streamlined workflow and reduced design time.

- Flexibility: Adaptability to diverse project requirements.

- Collaboration: Facilitated teamwork and shared project access.

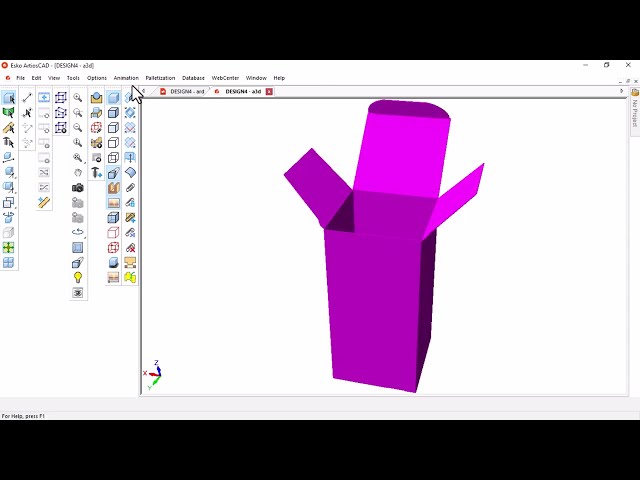

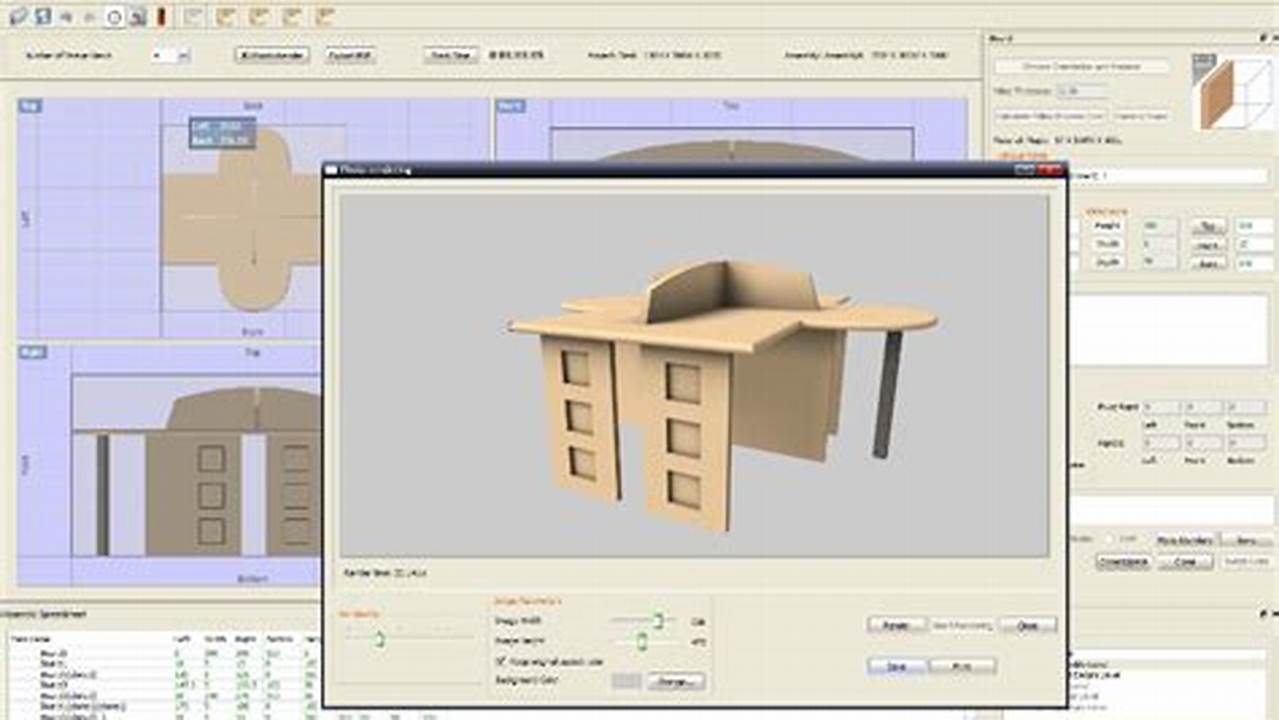

- Visualization: 3D modeling for realistic project previews.

- Simulation: Testing designs virtually before implementation.

- Material Optimization: Minimized waste and efficient material utilization.

- Customization: Tailored designs to meet specific needs.

- Knowledge Base: Access to project libraries and expert guidance.

- Integration: Compatibility with other software and hardware.

These aspects are interconnected and contribute to the overall effectiveness of design software for woodworking projects. For instance, accuracy and efficiency enable precise and timely project completion, while flexibility and collaboration facilitate seamless teamwork and adaptation to changing requirements. Furthermore, visualization and simulation capabilities provide invaluable insights into project outcomes, leading to informed decision-making and reduced risk of errors.

Accuracy

Accuracy in design and measurements is a critical component of design software for woodworking projects. Precise dimensions and angles are essential for ensuring that the final product meets the intended specifications and functions as expected. Design software provides tools and features that enable woodworkers to achieve a high degree of accuracy in their designs, including:

- Precise drawing tools: Design software offers a range of drawing tools that allow users to create precise lines, arcs, and shapes. These tools ensure that the dimensions and angles of the design are accurate, which is essential for creating functional and visually appealing woodworking projects.

- Measurement tools: Design software also includes measurement tools that allow users to measure the dimensions and angles of their designs. This ensures that all parts of the project are correctly sized and fit together properly.

- Snap-to features: Snap-to features allow users to align objects and elements in their designs with precision. This helps to ensure that all parts of the project are properly aligned and fit together correctly.

The accuracy provided by design software for woodworking projects has numerous benefits. First, it helps to reduce errors and waste during the construction process. When the design is accurate, the woodworker can be confident that the parts will fit together properly, which reduces the likelihood of mistakes and the need to rework or replace parts. Second, accuracy helps to ensure the structural integrity of the project. When the dimensions and angles are precise, the project is more likely to be strong and durable.

Overall, accuracy is a critical aspect of design software for woodworking projects. It helps to ensure that the final product meets the intended specifications and functions as expected, while also reducing errors and waste during the construction process.

Efficiency

Efficiency is a critical aspect of design software for woodworking projects. Streamlined workflow and reduced design time are key benefits of using design software, allowing woodworkers to work more efficiently and complete projects faster.

Design software streamlines the workflow by providing a digital platform for designing and planning projects. This eliminates the need for manual drafting and allows woodworkers to make changes and modifications quickly and easily. The software also includes features that help to automate repetitive tasks, such as creating joinery and hardware schedules. As a result, woodworkers can save a significant amount of time on the design process.

In addition to streamlining the workflow, design software can also help to reduce design time. The software provides a variety of tools and features that can help woodworkers to create designs more quickly and easily. For example, the software can be used to create parametric models, which allow woodworkers to make changes to the design without having to redraw the entire model. The software also includes a library of pre-designed components, which can be used to speed up the design process.

The efficiency benefits of design software for woodworking projects are significant. Woodworkers who use design software can save a significant amount of time on the design process, which can lead to increased productivity and profitability. In addition, the software can help woodworkers to create more accurate and detailed designs, which can lead to improved quality and customer satisfaction.

Flexibility

Flexibility is a key aspect of design software for woodworking projects, as it allows woodworkers to adapt their designs to meet the unique requirements of each project. This adaptability is essential for creating high-quality, functional, and visually appealing woodworking projects.

- Customizable parameters: Design software allows woodworkers to customize the parameters of their designs, such as the dimensions, materials, and joinery. This allows them to create designs that are tailored to the specific needs of their projects.

- Variety of templates and presets: Design software often includes a variety of templates and presets that can be used to create common woodworking projects, such as cabinets, tables, and chairs. These templates and presets can be customized to meet the specific requirements of each project.

- Integration with other software: Design software can be integrated with other software programs, such as CAD and CNC software. This allows woodworkers to import designs from other programs or to export designs to be used in other programs.

- Support for different file formats: Design software supports a variety of file formats, which allows woodworkers to share their designs with other woodworkers or with clients. This makes it easy to collaborate on projects and to share ideas.

The flexibility of design software for woodworking projects provides woodworkers with the freedom to create unique and personalized projects. This flexibility is essential for creating high-quality, functional, and visually appealing woodworking projects.

Collaboration

Collaboration is a critical component of design software for woodworking projects. It allows multiple users to work on the same project simultaneously, share ideas, and make changes in real time. This can significantly improve the efficiency and productivity of the design process.

One of the key benefits of collaboration in design software is that it allows woodworkers to share their expertise and knowledge with each other. For example, a woodworker who is experienced in cabinetmaking can share their knowledge with a woodworker who is new to the trade. This can help to improve the quality of the final product and reduce the risk of errors.

Another benefit of collaboration is that it allows woodworkers to work on projects from different locations. This can be especially helpful for woodworkers who are working on large projects that require a lot of time and effort. By using design software, woodworkers can share their designs with each other and work on the project together, regardless of their location.

Overall, collaboration is a critical component of design software for woodworking projects. It allows woodworkers to share their expertise, work on projects from different locations, and improve the efficiency and productivity of the design process.

Visualization

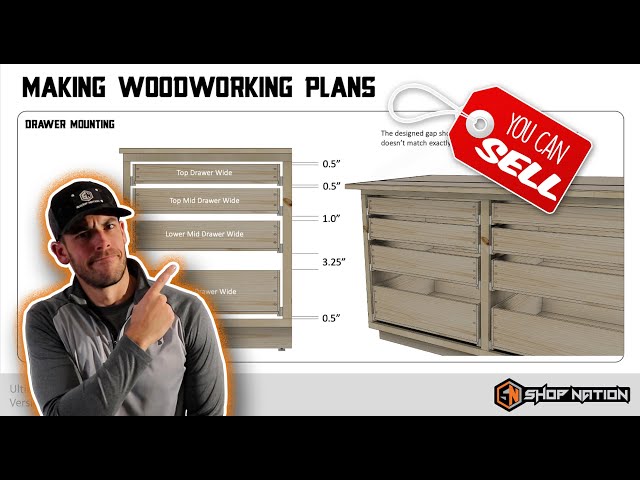

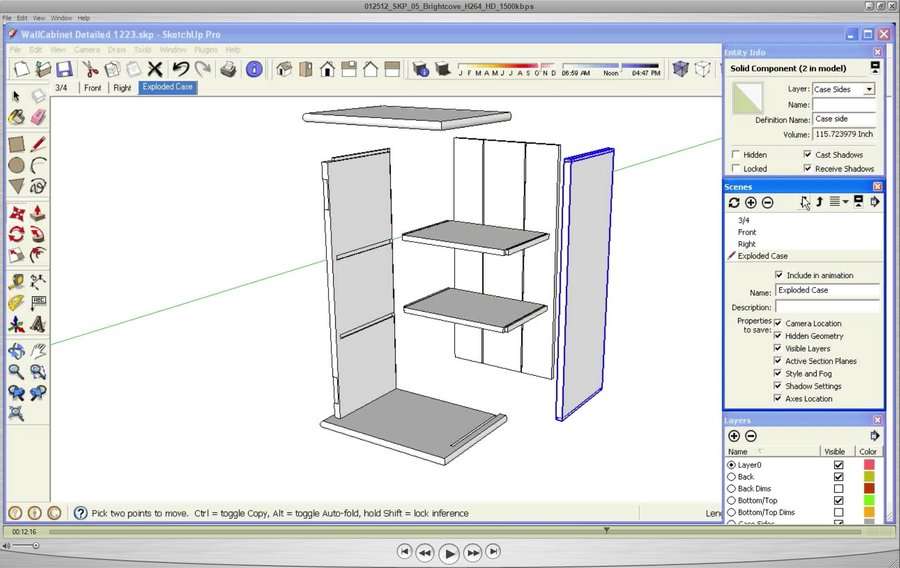

Visualization, through 3D modeling, is a critical component of design software for woodworking projects. It allows woodworkers to create realistic and detailed models of their projects, enabling them to visualize the final product before it is built. This can help to identify potential errors or design flaws early in the process, saving time and materials in the long run.

3D modeling also allows woodworkers to experiment with different design options and materials, helping them to make informed decisions about their projects. For example, a woodworker can use 3D modeling to compare the look of different wood species or hardware options, or to test the fit of different joinery techniques.

In addition, 3D modeling can be used to create realistic renderings of woodworking projects, which can be helpful for marketing and sales purposes. Potential customers can get a better sense of what the finished product will look like, which can help to increase sales.

Overall, visualization through 3D modeling is a powerful tool that can help woodworkers to design and build better projects. It can save time and materials by identifying potential errors early in the process, and it can help woodworkers to make informed decisions about their projects.

Simulation

In the realm of design software for woodworking projects, simulation plays a pivotal role, offering the ability to test designs virtually before their physical implementation. This capability empowers woodworkers to refine their designs, identify potential issues, and optimize their projects before committing to costly materials and labor.

- Realistic Material Properties: Simulation software incorporates realistic material properties, allowing woodworkers to accurately predict how their designs will behave under different loads and environmental conditions.

- Virtual Prototyping: With virtual prototyping, woodworkers can create digital models of their designs and subject them to real-world scenarios, such as stress testing and assembly simulations.

- Collision Detection: Simulation software can detect potential collisions between different components of a design, helping woodworkers identify and resolve interference issues early on.

- Joint Analysis: Simulation capabilities enable woodworkers to analyze the strength and durability of different joint designs, ensuring that their projects meet the required structural integrity.

By utilizing simulation features, woodworkers can gain valuable insights into the performance and functionality of their designs, leading to more informed decision-making and improved project outcomes. Simulation not only saves time and resources by reducing the need for physical prototyping, but also enhances the quality and precision of woodworking projects.

Material Optimization

In design software for woodworking projects, material optimization plays a critical role in reducing waste and maximizing the efficient use of materials. This feature allows woodworkers to plan their projects meticulously, minimizing material consumption and optimizing the utilization of available resources.

With material optimization capabilities, woodworkers can define material dimensions, specify cutting patterns, and arrange components to minimize waste. The software calculates the most efficient layout for cutting parts, taking into account grain direction, material defects, and optimal cutting strategies. This results in reduced material consumption, lower production costs, and less environmental impact.

For instance, a woodworker designing a kitchen cabinet using design software can optimize the layout of cabinet parts to minimize the number of cuts and reduce the amount of scrap material generated. The software can automatically adjust the dimensions and positions of parts to maximize material utilization, ensuring that the project is completed with minimal waste.

Moreover, material optimization features can be integrated with other aspects of design software, such as 3D modeling and simulation. This allows woodworkers to visualize and analyze their designs in detail, ensuring that material optimization is considered throughout the design and production process. By leveraging material optimization capabilities, woodworkers can enhance the sustainability and efficiency of their projects, contributing to responsible resource management and cost-effective production.

Customization

In the realm of design software for woodworking projects, customization stands as a cornerstone, enabling woodworkers to tailor their designs to meet the unique requirements of each project. This aspect empowers woodworkers to create highly personalized and functional designs that align precisely with their vision and the specific characteristics of their projects.

- Adaptable Dimensions: Design software provides the flexibility to modify the dimensions of individual parts and components, ensuring a perfect fit for any space or application. Woodworkers can adjust lengths, widths, heights, and angles to accommodate specific measurements and configurations.

- Diverse Material Selection: The software offers a comprehensive library of materials, allowing woodworkers to select from a wide range of species, grades, and finishes. This empowers them to choose the ideal materials for their projects, considering factors such as durability, aesthetics, and cost.

- Custom Joint Creation: Design software enables woodworkers to create custom joints, tailored to their specific design requirements. They can define the geometry, dimensions, and angles of joints, ensuring structural integrity and a seamless fit between components.

- Personalized Hardware Integration: The software allows for the integration of custom hardware, such as hinges, handles, and drawer slides. Woodworkers can specify the size, style, and placement of hardware, ensuring that it complements the overall design and functionality of the project.

Customization in design software for woodworking projects empowers woodworkers to unleash their creativity and craftsmanship, resulting in one-of-a-kind pieces that perfectly match their needs and preferences. It fosters innovation, precision, and the ability to bring unique design visions to life.

Knowledge Base

Within the context of design software for woodworking projects, the knowledge base component plays a pivotal role, providing woodworkers with access to a wealth of resources and expert insights. This aspect empowers them to tap into a collective knowledge pool, enhancing their design capabilities and project outcomes.

- Project Libraries: Extensive libraries of pre-designed projects, ranging from simple to complex, serve as a valuable source of inspiration and reference. These libraries offer a starting point for woodworkers, enabling them to adapt and customize designs to suit their specific needs.

- Material Properties Database: In-depth information on various wood species, including their properties, characteristics, and applications, empowers woodworkers to make informed material choices. This knowledge base helps them select the most appropriate materials for their projects, ensuring optimal performance and durability.

- Expert Tutorials and Guides: Step-by-step tutorials and comprehensive guides, authored by experienced woodworkers and industry experts, provide valuable insights into best practices, techniques, and troubleshooting methods. These resources enable woodworkers to learn from the knowledge and experience of others, enhancing their skills and expanding their capabilities.

- Community Forums and Support: Online forums and support groups foster a sense of community among woodworkers, allowing them to connect, share ideas, and seek advice from fellow enthusiasts and experts. This collaborative environment encourages knowledge sharing and problem-solving, contributing to the collective growth and advancement of woodworking skills.

The knowledge base component of design software for woodworking projects is an invaluable asset, empowering woodworkers with access to a vast repository of resources and expert guidance. It serves as a catalyst for learning, inspiration, and collaboration, enabling woodworkers to elevate their skills, produce high-quality projects, and navigate the complexities of woodworking with confidence.

Integration

In the context of design software for woodworking projects, integration plays a crucial role in enhancing the overall workflow and capabilities. Compatibility with other software and hardware enables seamless data exchange, efficient collaboration, and the utilization of specialized tools, empowering woodworkers to create intricate and high-quality projects.

- CAD/CAM Compatibility: Integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows for seamless transfer of designs between design and manufacturing stages. This eliminates the need for manual data entry, reducing errors and streamlining the production process.

- CNC Machine Control: Compatibility with CNC (computer numerical control) machines enables direct control of cutting tools and machinery from within the design software. This provides precise and automated fabrication, ensuring accuracy and repeatability in the production of complex parts.

- Project Management Integration: Integration with project management software allows woodworkers to track project timelines, manage resources, and collaborate with team members in a centralized platform. This enhances coordination and efficiency, especially in large-scale or collaborative projects.

- 3D Scanning Compatibility: Integration with 3D scanning devices enables the incorporation of real-world objects into digital designs. This is particularly useful for replicating existing structures, creating custom-fit components, or preserving historical artifacts.

The integration capabilities of design software for woodworking projects extend its functionality beyond the design phase, connecting it to various aspects of the production and management process. This seamless integration streamlines workflows, improves accuracy, and opens up new possibilities for innovation and collaboration in the field of woodworking.

Frequently Asked Questions about Design Software for Woodworking Projects

This section addresses commonly asked questions and provides concise answers to clarify various aspects of design software for woodworking projects.

Question 1: What are the key benefits of using design software for woodworking projects?

Answer: Design software offers numerous advantages, including enhanced accuracy, streamlined workflows, increased flexibility, facilitated collaboration, realistic visualization, and material optimization.

Question 2: How does design software help in material optimization?

Answer: Design software provides tools for efficient material utilization, allowing woodworkers to minimize waste by optimizing cutting patterns and arranging components to maximize material usage.

Question 3: Can design software be integrated with other tools and machinery?

Answer: Yes, design software often offers integration with CAD/CAM software, CNC machines, and project management tools, enabling seamless data exchange and automated production processes.

Question 4: What is the role of simulation in design software for woodworking?

Answer: Simulation capabilities allow woodworkers to test designs virtually before implementation, enabling them to identify potential issues, analyze structural integrity, and optimize designs for performance and functionality.

Question 5: How can design software assist in project collaboration?

Answer: Design software facilitates collaboration by allowing multiple users to work on the same project simultaneously, share ideas, make real-time changes, and access shared project libraries.

Question 6: What types of file formats are typically supported by design software for woodworking?

Answer: Design software generally supports a variety of file formats, including common CAD formats (DWG, DXF), image formats (JPG, PNG), and specialized woodworking file formats.

In summary, design software for woodworking projects empowers woodworkers with a comprehensive set of tools and capabilities to design, visualize, and optimize their projects. By leveraging these software tools, woodworkers can streamline their workflows, increase accuracy, enhance collaboration, and produce high-quality woodworking projects.

Transitioning to the next section, we will delve deeper into the technical aspects of design software for woodworking projects, exploring its features, functionalities, and advanced applications.

Tips for Enhancing Woodworking Projects with Design Software

This section provides valuable tips to help woodworkers optimize their use of design software for woodworking projects. By following these tips, woodworkers can harness the full potential of design software to create high-quality, efficient, and visually appealing projects.

Tip 1: Utilize Parametric Modeling for Flexibility: Leverage parametric modeling capabilities to modify designs easily by adjusting key parameters, ensuring adaptability and reducing the need for manual redrawing.

Tip 2: Explore Material Libraries for Informed Choices: Access comprehensive material libraries within the software to research and select the most suitable materials for your project, considering factors like durability, aesthetics, and cost.

Tip 3: Employ Simulation for Virtual Prototyping: Utilize simulation tools to test designs virtually, analyze structural integrity, identify potential issues, and optimize designs before physical implementation, saving time and resources.

Tip 4: Collaborate Effectively with Shared Access: Enable seamless collaboration by sharing designs with colleagues and clients, allowing real-time feedback, design iterations, and efficient project management.

Tip 5: Integrate with Other Tools for a Streamlined Workflow: Enhance your workflow by integrating design software with CAD/CAM software, CNC machines, and project management tools, automating tasks and improving data exchange.

Tip 6: Utilize 3D Visualization for Realistic Previews: Leverage 3D visualization capabilities to create realistic renderings of your designs, enabling thorough examination, client presentations, and marketing purposes.

Tip 7: Access Online Resources for Knowledge and Support: Explore online resources, forums, and tutorials to expand your knowledge, connect with other woodworkers, and seek expert advice when needed.

Tip 8: Practice Regularly to Master Software Functionality: Enhance your proficiency in using design software through regular practice and experimentation. Explore different features, experiment with various design techniques, and continuously refine your skills.

By incorporating these tips into their workflow, woodworkers can unlock the full potential of design software for woodworking projects. These tips empower woodworkers to design with greater accuracy, efficiency, and creativity, ultimately producing exceptional woodworking projects that meet the highest standards of quality and precision.

In the concluding section of this article, we will explore advanced applications of design software for woodworking projects, showcasing its versatility and transformative impact on the industry.

Conclusion

Design software for woodworking projects has revolutionized the industry, providing woodworkers with a powerful tool to design, visualize, and optimize their projects. Key insights emerging from this article include the enhanced accuracy, efficiency, and collaboration enabled by design software.

Firstly, design software empowers woodworkers with precision in measurements and angles, reducing errors and ensuring structural integrity. Secondly, it streamlines the design process, saving time and increasing productivity. Collaboration is also facilitated, allowing multiple users to work on projects simultaneously and share ideas.

The future of design software for woodworking projects holds exciting possibilities. As technology continues to advance, we can expect even more sophisticated tools for simulation, material optimization, and integration with other software and hardware. This will further enhance the capabilities of woodworkers, enabling them to create even more intricate and innovative projects.