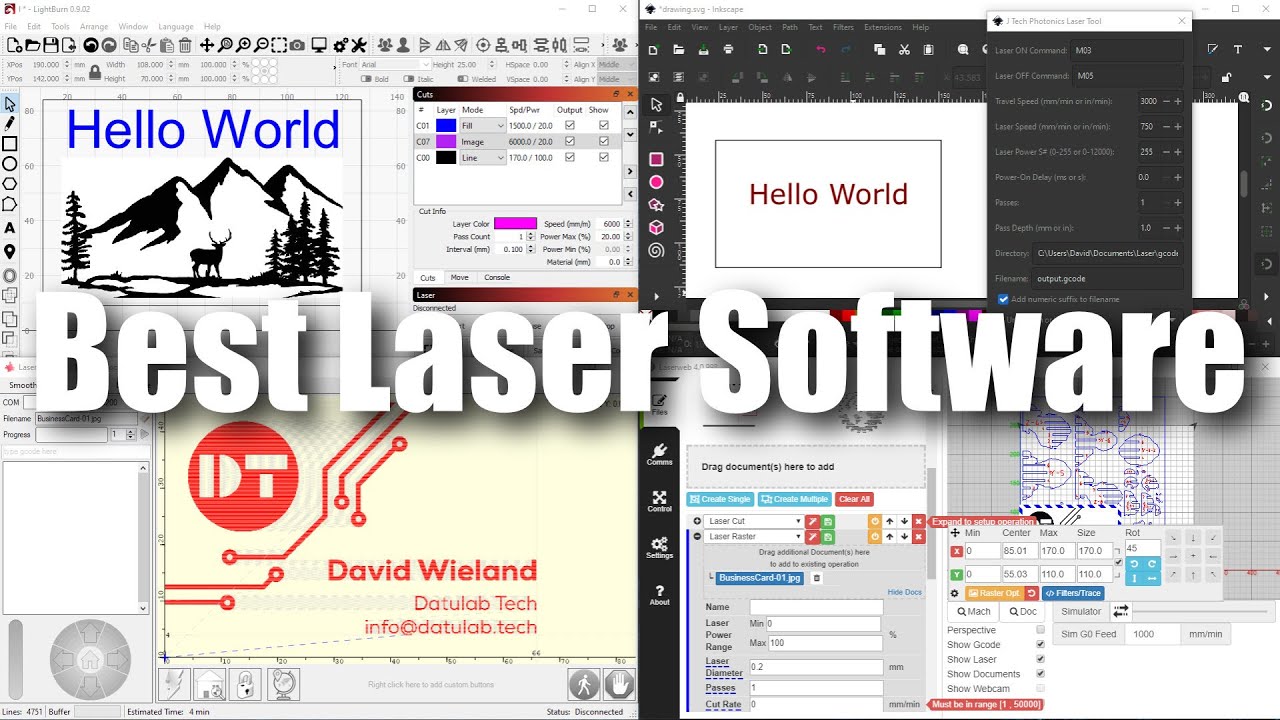

Design Software For Laser Engraving

Design software for laser engraving is a specialized application used to create precise and intricate designs that are then etched into surfaces using a laser engraver. These designs can vary from simple text and logos to complex artwork and patterns.

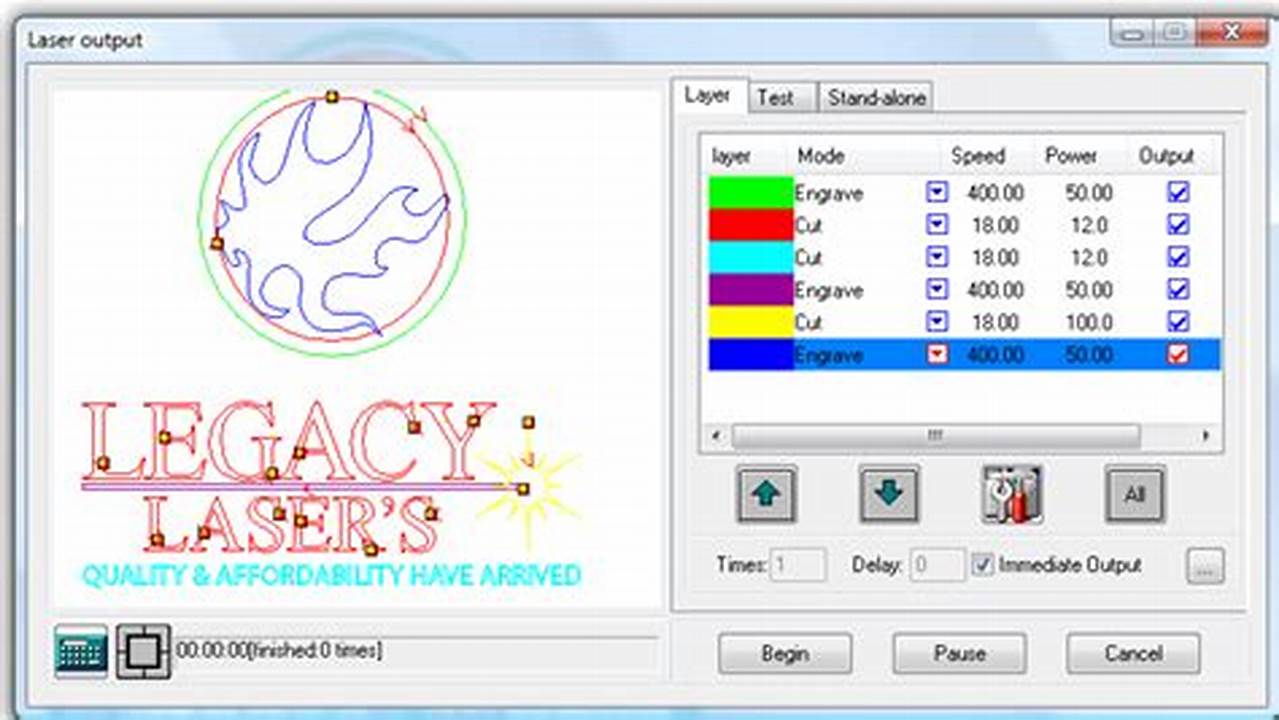

This software is vital for laser engraving, as it allows users to control the laser’s movements and settings with precision. It also provides tools for image editing, design creation, and path planning, ensuring that the final product meets the desired specifications.

Design software for laser engraving has revolutionized the industry, making it easier and more efficient to create high-quality engravings on a wide range of materials. With its user-friendly interface and powerful features, this software empowers users to unleash their creativity and bring their designs to life.

Design Software for Laser Engraving

Design software is the cornerstone of laser engraving, as it enables the creation of precise and intricate designs that are then etched into surfaces using laser engravers. These software applications provide a range of essential aspects that contribute to the overall effectiveness and versatility of laser engraving systems.

- User-friendly Interface

- Image Editing Tools

- Design Creation Capabilities

- Path Planning Features

- Material Compatibility

- Precision Control

- Versatility

- Compatibility

The user-friendly interface of design software makes it accessible to users of all skill levels, while the image editing tools allow for the manipulation of images to create custom designs. Design creation capabilities enable users to create their own unique designs from scratch, and path planning features ensure that the laser follows the desired path during engraving. Material compatibility is crucial for ensuring that the software is compatible with the materials being engraved, while precision control allows for precise and accurate engravings. Versatility enables the software to be used for a wide range of applications, and compatibility ensures that it can be used with different laser engraving systems.

User-friendly Interface

A user-friendly interface is paramount in design software for laser engraving, ensuring that users can easily navigate and utilize the software’s features to create their desired designs. This aspect encompasses several key facets that contribute to the overall usability and accessibility of the software.

-

Intuitive Layout

The software’s layout should be well-organized and logical, with clear menus and toolbars that are easy to understand and use, enabling users to quickly find the features they need.

-

Customization Options

The ability to customize the interface to suit individual preferences and workflows enhances usability. Users should be able to personalize toolbars, create shortcuts, and adjust settings to optimize their work environment.

-

Contextual Help

Providing contextual help and documentation within the software is essential for assisting users during the design process. This can include tooltips, tutorials, and user guides that offer guidance and support when needed.

-

Error Handling

Robust error handling mechanisms help users identify and resolve any issues they may encounter. Clear error messages and suggestions for troubleshooting ensure that users can quickly rectify errors and continue their work.

Overall, a user-friendly interface in design software for laser engraving empowers users of all skill levels to create complex designs with ease. By incorporating these facets, software developers can enhance the accessibility and usability of their applications, enabling users to maximize their creativity and efficiency.

Image Editing Tools

Image editing tools are a crucial component of design software for laser engraving, enabling users to manipulate and enhance images to create custom designs for engraving. These tools provide a wide range of functions and capabilities that empower users to transform their ideas into precise laser engravings.

One of the primary roles of image editing tools is to prepare images for laser engraving. This may involve adjusting the image’s size, cropping it to specific dimensions, or converting it to a suitable file format for engraving. Additionally, image editing tools allow users to enhance the image’s contrast, brightness, and color balance to optimize its appearance when engraved.

Beyond basic adjustments, image editing tools offer advanced features for creating complex designs. These features include the ability to add text, shapes, and other graphic elements to the image, as well as the ability to apply filters and effects to create unique and eye-catching designs. Furthermore, image editing tools allow users to combine multiple images and layers to create intricate compositions, expanding the possibilities for laser engraving.

In summary, image editing tools are an essential component of design software for laser engraving, providing users with the necessary capabilities to prepare, enhance, and create custom designs. By leveraging these tools, users can unlock the full potential of laser engraving, transforming their ideas into tangible works of art.

Design Creation Capabilities

Design creation capabilities are a pivotal component of design software for laser engraving, empowering users to transform their ideas into tangible, engraved designs. These capabilities enable users to create intricate and visually appealing designs from scratch, unlocking the full potential of laser engraving technology.

One of the key advantages of design creation capabilities is the ability to create custom designs tailored to specific needs and preferences. Unlike using pre-made templates or clip art, design creation capabilities provide the freedom to develop unique designs that align precisely with the user’s vision. This level of customization allows for the creation of personalized and meaningful engravings, adding a touch of individuality to any project.

Real-life examples of design creation capabilities in action can be found in various industries and applications. For instance, in the jewelry industry, design software allows jewelers to create intricate and delicate designs for rings, necklaces, and other pieces. In the manufacturing sector, design creation capabilities enable engineers to design custom parts and components with precision and accuracy. Additionally, in the arts and crafts domain, hobbyists can use design software to create unique engravings for home dcor, gifts, and other creative projects.

In summary, design creation capabilities are an essential component of design software for laser engraving, providing users with the tools to unleash their creativity and bring their ideas to life. By leveraging these capabilities, users can create custom designs that cater to their specific needs and applications, unlocking the full potential of laser engraving technology.

Path Planning Features

Path planning features are a crucial aspect of design software for laser engraving, as they determine the path that the laser will follow during the engraving process. This is essential for ensuring that the laser accurately and efficiently engraves the desired design into the material.

-

Optimization Algorithms

Optimization algorithms analyze the design and material properties to calculate the most efficient path for the laser to follow. This helps to minimize engraving time and improve the overall quality of the engraving.

-

Collision Avoidance

Collision avoidance features prevent the laser from colliding with any obstacles or fixtures in the engraving area. This is important for ensuring the safety of the laser and the operator.

-

Material Compensation

Material compensation features adjust the laser’s path based on the material being engraved. This is necessary because different materials have different properties that can affect the laser’s behavior.

-

Preview and Simulation

Preview and simulation features allow users to preview the laser’s path before actually engraving the material. This helps to identify any potential issues and make adjustments as needed.

Overall, path planning features are essential for ensuring the accuracy, efficiency, and safety of laser engraving. By providing users with powerful tools to control the laser’s path, design software empowers them to create high-quality engravings with ease.

Material Compatibility

Material compatibility is a critical aspect of design software for laser engraving, as it determines the types of materials that can be engraved and the quality of the finished product. The compatibility of the software with different materials ensures that the laser can interact with them effectively, producing clean and precise engravings.

-

Material Database

Comprehensive material databases within the software provide information on the compatibility of various materials with laser engraving. These databases include details on recommended laser settings, engraving speeds, and potential challenges for each material, guiding users in selecting the optimal settings for their projects.

-

Material Profiles

The ability to create and save material profiles within the software allows users to store and reuse optimal laser settings for specific materials. This streamlines the engraving process, ensuring consistent results and saving time when working with frequently used materials.

-

Material Testing

Integrated material testing features enable users to experiment with different laser settings and materials to determine the best combination for their projects. This allows for fine-tuning of engraving parameters to achieve the desired results, whether it’s intricate detailing or deep engraving.

-

Engraving Simulation

Engraving simulation features provide a virtual preview of the engraving process, allowing users to simulate the laser’s path and intensity on different materials. This helps identify potential issues, such as material scorching or excessive depth, enabling users to make adjustments beforethe engraving process.

In summary, material compatibility in design software for laser engraving plays a crucial role in ensuring the successful and efficient engraving of various materials. By providing comprehensive material databases, material profiles, material testing capabilities, and engraving simulation features, the software empowers users to achieve optimal results with a wide range of materials, expanding the possibilities for laser engraving applications.

Precision Control

Precision control is a critical aspect of design software for laser engraving, as it enables precise control over the laser’s movements and settings during the engraving process. This ensures that the software can produce highly accurate and detailed engravings, meeting the demands of various applications.

-

Laser Power Control

This feature allows users to precisely set the laser power, enabling them to adjust the intensity of the laser beam and achieve optimal results for different materials and engraving depths.

-

Engraving Speed Control

Precise control over the laser’s engraving speed is crucial for achieving consistent line widths and overall engraving quality. The software allows users to fine-tune the engraving speed to suit the material and design requirements.

-

Material Height Adjustment

For accurate and uniform engravings, the laser must be positioned at the correct height above the material. Design software with precision control features enables precise adjustment of the material height, ensuring optimal focus and engraving results.

-

Multi-Pass Engraving

This advanced feature allows users to specify multiple passes of the laser over the same area, enabling them to achieve deeper engravings or create intricate designs with varying depths.

Overall, precision control in design software for laser engraving empowers users to achieve highly accurate and detailed engravings. By providing precise control over laser power, engraving speed, material height, and multi-pass engraving capabilities, the software allows for optimal engraving outcomes, catering to the demands of diverse applications and materials.

Versatility

Versatility is a fundamental characteristic of design software for laser engraving, enabling it to cater to a wide range of applications and materials. This versatility stems from the software’s comprehensive feature set, which empowers users to create intricate designs, control laser parameters with precision, and work with diverse materials.

The versatility of design software for laser engraving manifests in several ways. Firstly, it allows users to create designs of varying complexity, from simple text and logos to detailed artwork and patterns. The software’s intuitive design tools and image editing capabilities make it accessible to users of all skill levels, fostering creativity and innovation.

Furthermore, the versatility of design software for laser engraving extends to its ability to control laser parameters with precision. Users can fine-tune laser power, engraving speed, and material height to achieve optimal results for different materials and engraving depths. This level of control ensures that the software can produce high-quality engravings that meet the demands of diverse applications.

In practical terms, the versatility of design software for laser engraving enables it to be used in a multitude of industries and applications. From personalized gift creation and home dcor to industrial part marking and medical device manufacturing, the software’s adaptability makes it an invaluable tool for makers, artists, and professionals alike.

Compatibility

Compatibility plays a vital role in design software for laser engraving, ensuring seamless integration with various components, materials, and systems. It encompasses diverse aspects that affect the software’s ability to interact and function effectively within its operating environment.

-

Device Connectivity

Compatibility with different laser engraving machines is essential, enabling the software to control and communicate with the laser engraver, ensuring accurate and precise engraving results.

-

Material Support

The software should support a wide range of materials, allowing users to engrave on diverse surfaces such as wood, metal, plastic, and glass, catering to various application needs.

-

File Formats

Compatibility with industry-standard file formats, such as DXF, SVG, and AI, enables seamless import and export of designs, facilitating collaboration and exchange of artwork.

-

Operating Systems

Compatibility with different operating systems, including Windows, Mac, and Linux, ensures that the software can be used on various computers and workstations, providing flexibility and accessibility.

Overall, compatibility is a crucial aspect of design software for laser engraving, allowing it to work harmoniously with different components, materials, and systems. This ensures seamless operation, versatility, and the ability to meet the diverse requirements of laser engraving applications.

FAQs on Design Software for Laser Engraving

This section provides answers to frequently asked questions regarding design software for laser engraving, covering its functionalities, compatibility, and usage.

Question 1: What is design software for laser engraving used for?

Design software for laser engraving is used to create and edit designs that are then engraved onto various materials using a laser engraver. It provides tools for image editing, design creation, and laser parameter control, enabling users to produce intricate and precise engravings.

Question 2: What types of materials are compatible with design software for laser engraving?

Design software for laser engraving supports a wide range of materials, including wood, metal, plastic, glass, and leather. The compatibility with different materials allows users to create engravings on diverse surfaces, catering to various applications and industries.

Question 3: Is design software for laser engraving easy to use?

Yes, many design software for laser engraving are designed with user-friendly interfaces and intuitive tools. They offer features such as drag-and-drop functionality, pre-designed templates, and tutorials, making them accessible to users of all skill levels.

Question 4: Can I import my own designs into design software for laser engraving?

Yes, most design software for laser engraving allows users to import their own designs in various file formats, such as DXF, SVG, and AI. This enables users to work with existing artwork or create their own unique designs from scratch.

Question 5: How precise is design software for laser engraving?

Design software for laser engraving provides precise control over laser parameters, including power, speed, and resolution. This allows users to achieve high-quality engravings with sharp lines, smooth curves, and accurate details.

Question 6: Can I use design software for laser engraving on different operating systems?

Compatibility with different operating systems varies depending on the specific software. Some design software for laser engraving is compatible with Windows, Mac, and Linux operating systems, while others may be limited to one or two operating systems.

These FAQs provide a general overview of design software for laser engraving, addressing common questions about its capabilities, compatibility, and ease of use. As you explore further, you will discover additional aspects and functionalities of design software that can enhance your laser engraving projects.

Next, we will delve into the advanced features and functionalities of design software for laser engraving, exploring how these capabilities can empower users to create stunning and intricate engravings.

Tips for Choosing Design Software for Laser Engraving

Selecting the right design software is crucial for successful laser engraving projects. Here are five essential tips to help you choose the software that best meets your needs:

-

Consider Your Skill Level

Choose software that aligns with your skill level. If you’re a beginner, look for user-friendly software with intuitive features. Advanced users may prefer software with more complex capabilities.

-

Check Material Compatibility

Ensure that the software supports the materials you plan to engrave. Different materials require specific laser settings, and compatible software will provide optimal results.

-

Evaluate Precision Control

Precise control over laser parameters is essential for high-quality engravings. Look for software that offers precise control over power, speed, and resolution.

-

Consider Versatility

Choose software that can handle a variety of design tasks, from simple text to complex artwork. Versatility ensures that the software can meet your evolving needs.

-

Explore Compatibility

Make sure the software is compatible with your laser engraver and operating system. Compatibility issues can lead to errors and unexpected results.

By following these tips, you can choose design software that empowers you to create stunning and precise laser engravings. These tips lay the foundation for exploring the advanced features and capabilities of design software in the next section.

In the final section, we will discuss the impact of design software on the future of laser engraving, highlighting its potential to revolutionize the industry and open up new possibilities for creativity and innovation.

Conclusion

In exploring the realm of design software for laser engraving, this article has illuminated its significance as a cornerstone of the laser engraving process. Through its comprehensive features and functionalities, design software empowers users to unleash their creativity and produce intricate, precise engravings on a wide range of materials.

Key points highlighted throughout the article include the user-friendly interface, image editing tools, design creation capabilities, path planning features, material compatibility, precision control, versatility, and compatibility of design software. These aspects work in harmony, enabling users to create stunning engravings that meet their specific needs and applications.

The future of laser engraving looks promising, with design software continuing to play a pivotal role. Advanced features such as artificial intelligence and cloud-based collaboration are poised to further revolutionize the industry, opening up new possibilities for innovation and creativity. As technology continues to evolve, design software for laser engraving will remain an indispensable tool for makers, artists, and professionals alike.