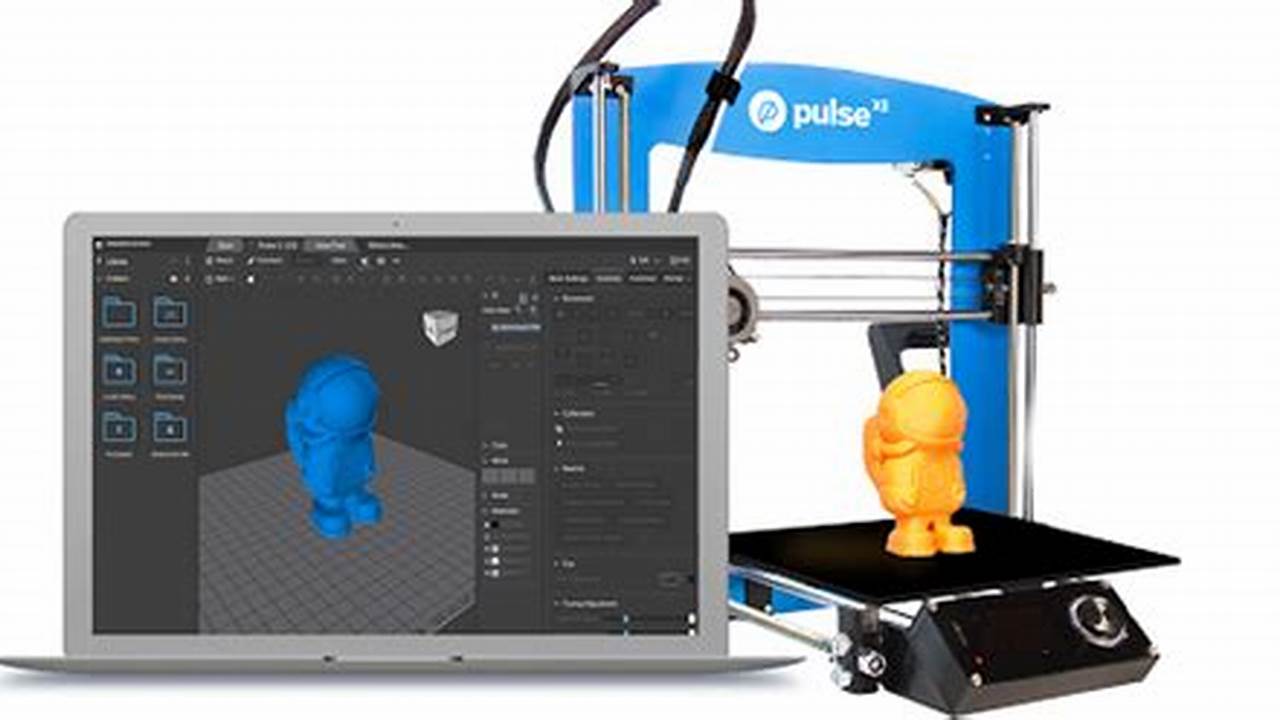

Design Software For 3d Printing

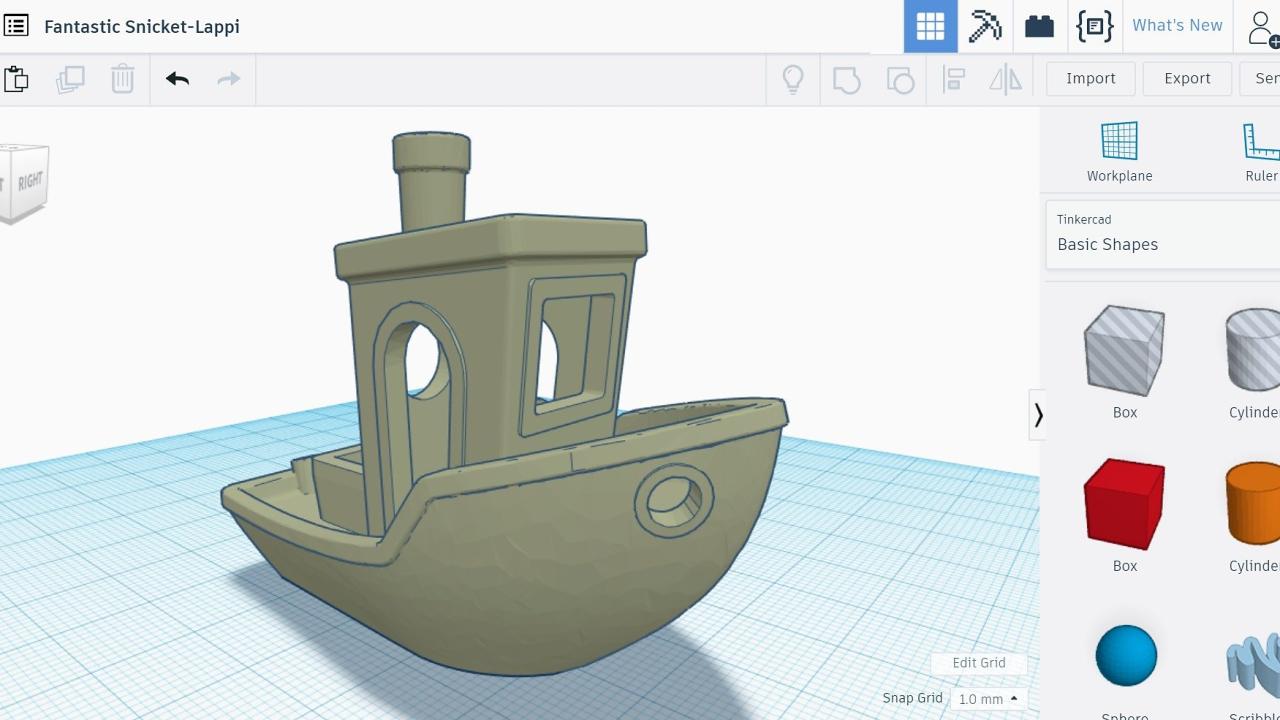

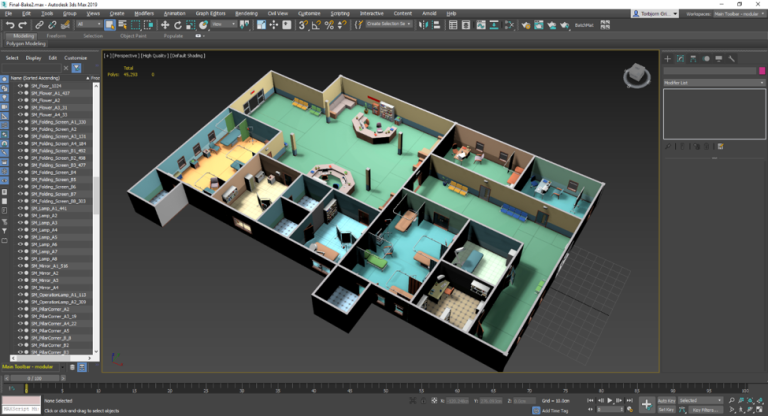

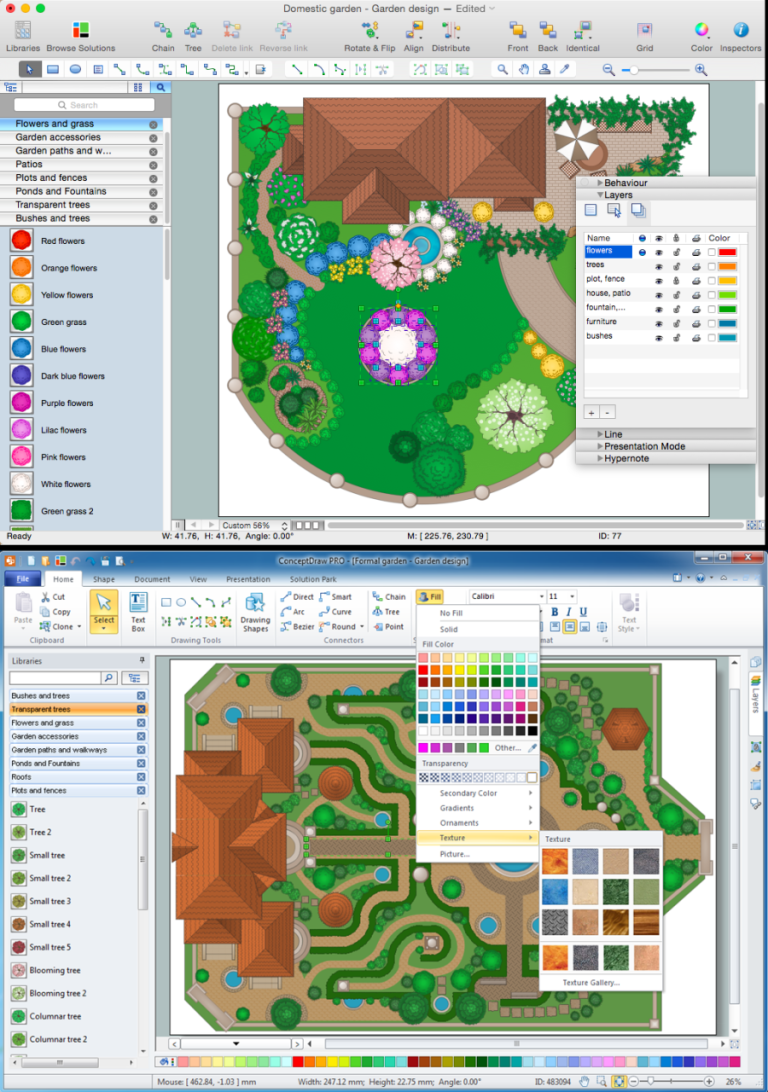

Design software for 3D printing is a type of computer-aided design (CAD) software used to create 3D models for 3D printing. It allows users to create complex and detailed designs that can be printed on a 3D printer. An example of design software for 3D printing is Blender, an open-source software that provides tools for modeling, sculpting, animation, rendering, compositing, and motion tracking.

Design software for 3D printing has revolutionized the way products are designed and manufactured. It enables users to create prototypes and models quickly and easily, reducing the need for expensive and time-consuming traditional manufacturing methods. One of the key historical developments in design software for 3D printing was the introduction of parametric modeling, which allows users to create models that can be easily modified by changing parameters.

In this article, we will explore the different types of design software for 3D printing, discuss the benefits of using such software, and provide tips for choosing the right software for your needs. We will also highlight some of the challenges and limitations of design software for 3D printing, and discuss the future of this technology.

Design Software for 3D Printing

Design software for 3D printing is essential for creating high-quality 3D models that can be printed on a 3D printer. Key aspects of design software for 3D printing include:

- Modeling tools

- Slicing capabilities

- Material support

- User interface

- File compatibility

- Price

- Community support

- Updates and development

These aspects are all important to consider when choosing design software for 3D printing. Modeling tools determine the types of models that can be created, while slicing capabilities determine the quality of the printed model. Material support determines which materials can be used for printing, and the user interface affects how easy the software is to use. File compatibility is important for sharing models with others, and price is a factor for many users. Community support can provide help and advice, and updates and development ensure that the software is always up-to-date with the latest features. By considering all of these aspects, users can choose the best design software for their needs.

Modeling tools

Modeling tools are a crucial aspect of design software for 3D printing, as they allow users to create the 3D models that will be printed. There are many different types of modeling tools available, each with its own strengths and weaknesses. Some of the most common types of modeling tools include:

-

Solid modeling

Solid modeling tools allow users to create 3D models of solid objects. These models are typically created by extruding 2D shapes into 3D space, or by rotating 2D shapes around an axis to create a solid object. -

Surface modeling

Surface modeling tools allow users to create 3D models of surfaces. These models are typically created by manipulating points, lines, and curves to create a surface. Surface modeling is often used to create organic shapes that would be difficult to create with solid modeling. -

Mesh modeling

Mesh modeling tools allow users to create 3D models of objects by connecting points, lines, and faces to form a mesh. Mesh modeling is often used to create complex shapes that would be difficult to create with solid or surface modeling. -

Sculpting tools

Sculpting tools allow users to create 3D models by manipulating a virtual piece of clay. Sculpting tools are often used to create organic shapes that would be difficult to create with other modeling tools.

The choice of which modeling tools to use depends on the specific needs of the user. For example, solid modeling is best suited for creating models of objects that have a well-defined shape, such as a cube or a sphere. Surface modeling is best suited for creating models of objects that have a smooth surface, such as a car or a boat. Mesh modeling is best suited for creating models of objects that have a complex shape, such as a human figure or a tree. Sculpting tools are best suited for creating models of organic shapes, such as animals or plants.

Slicing capabilities

Slicing capabilities are a critical component of design software for 3D printing. Slicing software takes a 3D model and divides it into thin layers, which are then printed one layer at a time by the 3D printer. The quality of the printed model depends on the quality of the slicing, so it is important to use slicing software that is specifically designed for the type of 3D printer being used.

There are many different slicing software programs available, each with its own strengths and weaknesses. Some of the most popular slicing software programs include Cura, Simplify3D, and PrusaSlicer. These programs allow users to control a variety of slicing settings, such as layer height, infill density, and print speed. By adjusting these settings, users can optimize the quality of the printed model for their specific needs.

In addition to controlling slicing settings, slicing software also allows users to preview the printed model before it is printed. This allows users to check for errors in the model or to make sure that the model is positioned correctly on the print bed. Slicing software also provides users with estimated print times and material usage, which can be helpful for planning printing projects.

Slicing capabilities are essential for design software for 3D printing. By using slicing software, users can control the quality of the printed model, preview the model before it is printed, and estimate print times and material usage. This information is essential for successful 3D printing.

Material support

Material support is a critical component of design software for 3D printing. It allows users to create models that can be printed with different materials, such as plastic, metal, and ceramic. Material support is also essential for creating models with complex geometries, such as overhangs and undercuts. Without material support, these features would collapse during printing.

There are many different types of material support available in design software for 3D printing. The most common type of material support is temporary support, which is printed along with the model and then removed after printing is complete. Temporary support is typically made from a water-soluble material, such as PVA. Other types of material support include permanent support, which is designed to remain in place after printing, and sacrificial support, which is printed in areas that are difficult to reach with other types of support. Sacrificial support is typically made from a brittle material, such as PLA.

The choice of which material support to use depends on the specific needs of the user. For example, temporary support is best suited for models with complex geometries that require a high level of support. Permanent support is best suited for models that require a high level of strength and durability. Sacrificial support is best suited for models that are difficult to reach with other types of support.

Material support is an essential component of design software for 3D printing. By using material support, users can create models that can be printed with different materials and complex geometries. This information is essential for successful 3D printing.

User interface

The user interface (UI) is a critical component of design software for 3D printing. It is the part of the software that allows users to interact with the software and create 3D models. A well-designed UI can make it easy for users to learn and use the software, while a poorly designed UI can make it difficult and frustrating. There are a number of factors to consider when designing a UI for design software for 3D printing, including:

– Ease of use: The UI should be easy to understand and use, even for beginners. Users should be able to find the tools and features they need quickly and easily, and they should be able to complete tasks without having to consult the documentation or online help. – Flexibility: The UI should be flexible enough to accommodate a variety of user needs. Some users may need a simple UI with only the most basic features, while other users may need a more complex UI with a wider range of features. The UI should be able to adapt to the needs of different users without becoming cluttered or confusing. – Responsiveness: The UI should be responsive and provide feedback to users as they interact with the software. For example, the UI should highlight the selected tool or feature, and it should provide visual feedback when users make changes to the model. – Aesthetics: The UI should be aesthetically pleasing and consistent with the overall design of the software. The colors, fonts, and icons should be chosen carefully to create a visually appealing and user-friendly interface.

Real-life examples of well-designed UIs for design software for 3D printing include Blender, SolidWorks, and AutoCAD. These software programs have UIs that are easy to understand and use, and they provide a wide range of features and tools to meet the needs of different users. The UIs are also responsive and provide feedback to users as they interact with the software. As a result, these software programs are popular among both beginner and experienced users.

The practical applications of understanding the connection between user interface and design software for 3D printing are numerous. For example, this understanding can help software developers to create UIs that are more user-friendly and efficient. It can also help users to choose the right software for their needs and to use the software more effectively. In addition, this understanding can help to promote the adoption of 3D printing technology by making it more accessible to a wider range of users.

File compatibility

File compatibility is a critical component of design software for 3D printing. It allows users to share models with others, collaborate on projects, and use models created in other software programs. Without file compatibility, it would be very difficult to use design software for 3D printing effectively.

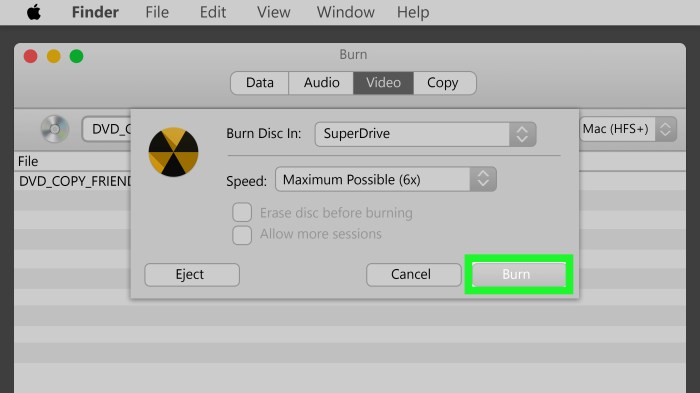

There are many different file formats used for 3D printing, and it is important to choose a file format that is compatible with the software you are using. Some of the most common file formats for 3D printing include STL, OBJ, and AMF. STL is a simple file format that is supported by most 3D printing software programs. OBJ is a more complex file format that supports more features, such as textures and materials. AMF is a newer file format that is designed to be more efficient and easier to use than STL and OBJ.

When choosing a file format for 3D printing, it is important to consider the following factors:

- The software you are using

- The features you need

- The size of the file

- The compatibility of the file with other software programs

By understanding the connection between file compatibility and design software for 3D printing, users can choose the right file format for their needs and ensure that they can share and use models effectively.

Price

When it comes to design software for 3D printing, price is an important consideration. The cost of software can vary significantly depending on the features offered, the level of support provided, and the target market. Understanding the different aspects of price can help users make informed decisions about which software to purchase.

-

Upfront cost

The upfront cost of design software for 3D printing can range from free to thousands of dollars. Free software is often open-source and community-supported, while commercial software typically offers a wider range of features and support options. -

Subscription cost

Some design software for 3D printing is sold on a subscription basis. This means that users pay a monthly or annual fee to access the software. Subscription costs can vary depending on the features included and the length of the subscription. -

Training and support

Many software vendors offer training and support services to help users get the most out of their software. These services can be included in the purchase price of the software or offered as an additional cost. -

Return on investment

When evaluating the price of design software for 3D printing, it is important to consider the return on investment (ROI). ROI is the amount of money that a user can expect to make back from using the software. ROI can be difficult to calculate, but it is important to consider when making a purchase decision.

The price of design software for 3D printing can vary significantly depending on the specific needs of the user. By understanding the different aspects of price, users can make informed decisions about which software to purchase and maximize their ROI.

Community support

Community support is a critical component of design software for 3D printing. It provides users with a wealth of resources and support that can help them to learn the software, troubleshoot problems, and share ideas. Without community support, many users would find it difficult to use design software for 3D printing effectively.

There are many different ways that community support can be provided for design software for 3D printing. Some of the most common methods include:

- Online forums

- Social media groups

- Documentation and tutorials

- Community-developed plugins and add-ons

- In-person workshops and meetups

These resources can provide users with a wealth of information and support. For example, online forums can be a great place to ask questions about the software, share tips and tricks, and get help from other users. Social media groups can be a good way to connect with other users and stay up-to-date on the latest news and developments in the software. Documentation and tutorials can provide users with a structured way to learn the software and its features. Community-developed plugins and add-ons can extend the functionality of the software and make it more versatile. In-person workshops and meetups can provide users with an opportunity to learn from other users and get hands-on experience with the software.

The practical applications of understanding the connection between community support and design software for 3D printing are numerous. For example, this understanding can help software developers to create software that is more user-friendly and supportive. It can also help users to choose the right software for their needs and to use the software more effectively. In addition, this understanding can help to promote the adoption of 3D printing technology by making it more accessible to a wider range of users.

Updates and development

Updates and development are critical components of design software for 3D printing. They ensure that the software is up-to-date with the latest features and technologies, and that it is compatible with the latest 3D printers and materials. Without regular updates and development, design software for 3D printing would quickly become outdated and unusable.

There are many different types of updates and development that can be made to design software for 3D printing. Some updates are minor, such as bug fixes and performance improvements. Other updates are major, such as new features and functionality. Major updates are typically released on a regular schedule, such as once per year. Minor updates are typically released more frequently, such as once per month or even more frequently.

Real-life examples of updates and development in design software for 3D printing include the addition of new modeling tools, support for new file formats, and improvements to slicing algorithms. These updates and developments have made design software for 3D printing more powerful and versatile, and they have made it possible to create more complex and sophisticated 3D models.

The practical applications of understanding the connection between updates and development and design software for 3D printing are numerous. For example, this understanding can help software developers to create software that is more up-to-date and feature-rich. It can also help users to choose the right software for their needs, and to use the software more effectively. In addition, this understanding can help to promote the adoption of 3D printing technology by making it more accessible to a wider range of users.

FAQs on Design Software for 3D Printing

This FAQ section addresses frequently asked questions about design software for 3D printing, clarifying its nature, applications, benefits, and limitations.

Question 1: What exactly is design software for 3D printing?

Answer: Design software for 3D printing, often referred to as CAD (computer-aided design) software, allows users to create 3D models for printing on 3D printers. It provides a virtual environment for designing and modifying 3D objects.

Question 2: What are the advantages of using design software for 3D printing?

Answer: Design software for 3D printing offers several benefits, such as precision in model creation, the ability to create complex geometries, prototyping capabilities, and the flexibility to make design changes before printing.

Question 3: What are the key features to look for in design software for 3D printing?

Answer: Important features to consider include modeling tools, slicing capabilities, material compatibility, user interface, file compatibility, community support, updates, and development.

Question 4: Can I use design software for 3D printing if I have no prior experience in 3D modeling?

Answer: Many design software options are beginner-friendly, providing tutorials, documentation, and online resources to assist users with little to no 3D modeling experience.

Question 5: What are the limitations of design software for 3D printing?

Answer: Design software for 3D printing may have limitations in terms of processing large or complex models, compatibility with specific 3D printers, or the learning curve associated with mastering its features.

Question 6: What is the future outlook for design software for 3D printing?

Answer: The future of design software for 3D printing involves advancements in artificial intelligence (AI), cloud computing, and generative design, leading to more intuitive and powerful tools for users.

In summary, design software for 3D printing empowers users to create intricate 3D models for various applications. By understanding its capabilities and limitations, users can leverage this technology effectively.

As we delve further into the realm of design software for 3D printing, the next section will explore specific software options and their unique features.

Tips for Working with Design Software for 3D Printing

This section provides a set of practical tips to enhance your experience with design software for 3D printing and achieve optimal results.

Tip 1: Choose the Right Software: Consider your skill level, project requirements, and budget when selecting design software.

Tip 2: Learn the Basics: Familiarize yourself with the software’s interface, tools, and basic modeling techniques.

Tip 3: Start with Simple Models: Begin with basic shapes and gradually increase the complexity of your designs.

Tip 4: Utilize Online Resources: Access tutorials, documentation, and forums to enhance your knowledge and troubleshoot.

Tip 5: Pay Attention to File Formats: Understand and use appropriate file formats for your software and 3D printer.

Tip 6: Optimize Your Models: Ensure your models are watertight, manifold, and scaled appropriately for printing.

Tip 7: Leverage Community Support: Join forums, online groups, and attend workshops to connect with other users and seek assistance.

Tip 8: Keep Up with Updates: Regularly update your design software to benefit from new features and bug fixes.

By following these tips, you can effectively utilize design software for 3D printing, optimize your workflow, and produce high-quality 3D models for successful printing.

As you master the techniques and best practices discussed in this section, you will be well-equipped to navigate the advanced topics and considerations explored in the concluding section of this article.

Conclusion

Design software for 3D printing has revolutionized the way objects are designed and manufactured. This article has explored the essential components of such software, including modeling tools, slicing capabilities, user interface, and community support. By understanding these components and their interconnections, users can select the right software for their needs and maximize its potential.

Key takeaways from this article include the importance of choosing software that aligns with one’s skill level and project requirements, the value of community support and online resources for learning and troubleshooting, and the need to keep updated with software advancements for optimal performance. As technology continues to progress, design software for 3D printing will play an increasingly vital role in industries ranging from engineering and architecture to healthcare and consumer products.